Grinding is a fundamental process in various industries, including manufacturing, construction, and metalworking. To achieve optimal results, it's essential to master the techniques of grinding with vitrified wheels. To get more information about vitrified grinding wheels, you can navigate to this site.

The Basics of Vitrified Grinding Wheels

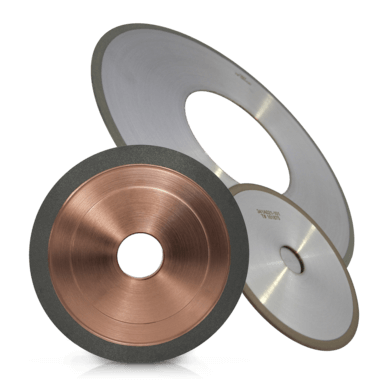

Vitrified grinding wheels are made from a mixture of abrasive grains, bonding agents, and fillers that are fused together at high temperatures. These wheels are known for their durability, precision, and versatility, making them the go-to choice for various grinding applications. Here are some key points to understand about vitrified grinding wheels:

Composition of Vitrified Wheels

- Abrasive grains such as aluminum oxide, silicon carbide, or ceramic are used to provide cutting action.

- Bonding agents like clay, feldspar, or glass bind the abrasive grains together and determine the overall strength of the wheel.

- Fillers help in spacing out the abrasive grains evenly and improving the performance of the wheel.

Advantages of Vitrified Wheels

- Highly resistant to heat and wear, making them suitable for heavy-duty grinding tasks.

- Precise and consistent grinding results due to the controlled structure of the wheel.

- Available in a wide range of shapes, sizes, and abrasive types to suit different applications.

- Less likely to load or glaze, ensuring continuous cutting action and improved efficiency.

Grinding Techniques for Novices

If you're new to grinding with vitrified wheels, mastering the basic techniques is crucial for achieving quality results and ensuring safety. Here are some tips to help novices improve their grinding skills:

Proper Setup and Inspection

- Ensure the wheel is securely mounted on the grinder and aligned correctly before starting.

- Inspect the wheel for any damage, cracks, or signs of wear that could compromise safety.

- Adjust the speed and feed rate according to the material being ground to prevent overheating or damage.

Correct Grinding Practices

- Maintain a consistent pressure and angle while grinding to avoid uneven wear on the wheel.

- Avoid excessive force or aggressive grinding, as it can lead to overheating and premature wear of the wheel.

- Use coolant or lubricant to dissipate heat and prolong the life of the wheel during grinding operations.

Advanced Grinding Techniques for Pros

For experienced professionals looking to elevate their grinding skills with vitrified wheels, mastering advanced techniques can lead to improved efficiency and precision. Here are some strategies to help pro-level operators enhance their grinding performance:

Optimizing Wheel Selection

- Choose the right type of vitrified wheel based on the material being ground, hardness, and desired surface finish.

- Experiment with different grit sizes, bond types, and wheel configurations to achieve optimal results for specific applications.

- Consider using specialized wheels for high-speed or precision grinding tasks that require superior control and accuracy.

Advanced Grinding Strategies

- Implement multi-pass grinding techniques to achieve finer surface finishes and tighter tolerances.

- Utilize dressing tools to maintain the sharpness and shape of the grinding wheel during extended use.

- Explore advanced cooling systems or techniques to optimize heat dissipation and prevent thermal damage during grinding.

Whether you're a novice or a pro, mastering the art of grinding with vitrified wheels requires practice, patience, and a solid understanding of the fundamentals. By following the tips and techniques outlined in this guide, you can elevate your grinding skills and achieve exceptional results in your grinding operations.

Leave a Reply